Aluzinc Z32

Aluzinc Z32 Specification

- Smell

- Odorless

- Structural Formula

- Fe base with continuous Al-Zn alloy coating

- Purity

- Al, Zn, and Si Coating ~99.9%

- Product Type

- Aluzinc Coated Steel

- Usage

- Building and construction, sheet fabrication, appliance manufacturing etc.

- Properties

- Corrosion resistant, high thermal reflectivity, aesthetic surface finish, durable, weldable, excellent paint adhesion, high temperature resistance

- EINECS No

- 235-760-8

- Grade

- Z32

- Shape

- Sheet, Coil

- Molecular Formula

- Fe base, coated with Al-Zn alloy

- Storage

- Store in dry, covered, ventilated area to protect from moisture and contamination

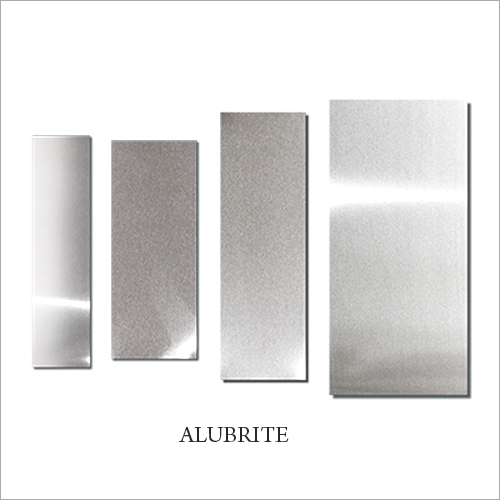

- Appearance

- Metallic, Silver glossy finish

- Application

- Roofing, cladding, pre-painted steel manufacturing, appliance bodies, automotive parts, construction, industrial panels

- Shelf Life

- Indefinite under proper storage conditions

- CAS No

- 12597-69-2

- Melting Point

- ~600C (Coating layer) / Steel base: ~1425-1540C

- Ingredients

- Steel, Aluminium (approx 55%), Zinc (approx 43.4%), Silicon (approx 1.6%)

- Solubility

- Insoluble in water

- Physical Form

- Solid Sheet

- HS Code

- 72104900

- Poisonous

- NO

- Density

- 7.85 Gram per cubic centimeter(g/cm3)

- Coating Weight

- Z32 (approx. 32 g/m² on both sides total)

- Width Range

- 600 mm to 1250 mm

- Standard Thickness Range

- 0.18 mm to 1.2 mm

- Tensile Strength

- 270-350 MPa (typical)

- Paintability

- Excellent paint adhesion when properly pre-treated

- Formability

- Good for bending, roll forming, and drawing

- Surface Finish

- Regular Spangle, Minimized Spangle, Chromated or Non-chromated, Oiled or Unoiled

- Corrosion Resistance

- Superior to conventional galvanized steel in most environments

- Thermal Reflectivity

- Excellent, up to 80% reflectance

About Aluzinc Z32

Explore Versatile Applications of Aluzinc Z32

Aluzinc Z32 is expertly utilized in building and construction projects, notably for roofing, cladding, and industrial panels. The typical application method involves sheet fabrication, roll forming, and drawing, allowing for tailored architectural and structural uses. Renowned manufacturers and service providers use Aluzinc Z32 for pre-painted steel production, appliance bodies, and automotive parts, demonstrating its adaptability across industries. Beyond construction, it seamlessly integrates into appliances, automotive, and panel manufacturing, maximizing design potential and durability in diverse environments.

Payment Terms and Market Presence for Aluzinc Z32

Expenditure on Aluzinc Z32 is streamlined via flexible payment terms, supporting smooth order processing and timely delivery. The product is primarily available in the Indian domestic market, where demand is consistently high due to its acclaimed properties. Certified by leading industry standards, Aluzinc Z32 assures reliability for all purchases. Major exporters, suppliers, and wholesalers in India facilitate easy access and prompt shipment, ensuring buyers receive quality material with trusted documentation and efficient service.

FAQ's of Aluzinc Z32:

Q: How should Aluzinc Z32 sheets be stored for optimal lifespan?

A: Aluzinc Z32 sheets should be stored in a dry, covered, and well-ventilated area to protect from moisture and contamination. Proper storage ensures an indefinite shelf life and preserves the product's acclaimed corrosion resistance.Q: What are the main benefits of using Aluzinc Z32 over conventional galvanized steel?

A: Aluzinc Z32 offers superior corrosion resistance, enhanced thermal reflectivity, and excellent paint adhesion. These features result in longer-lasting, visually appealing finishes that perform well in high-temperature and demanding environments.Q: Where is Aluzinc Z32 most commonly used in construction and manufacturing?

A: It is widely utilized in roofing, cladding, appliance bodies, and industrial panels. Additionally, it finds application in automotive parts and pre-painted steel manufacturing, making it a versatile choice for various sectors.Q: What application methods are suitable for Aluzinc Z32?

A: Aluzinc Z32 can be processed through bending, roll forming, and drawing. These methods allow for easy shaping and fabrication, catering to diverse building, appliance, and industrial panel needs.Q: How is the order processing and delivery for Aluzinc Z32 managed?

A: Order processing is handled by certified suppliers and exporters, ensuring efficient handling. Delivery is arranged to ensure timely shipment while maintaining the material's quality and documentation integrity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Aluminium Anodising Category

Aluzincate 50B

Usage : Surface protection, anticorrosive coating

Smell : Other, Odorless

Grade : Technical Grade

Storage : Other, Store in cool, dry place in tightly sealed container

Properties : Good corrosion resistance, enhanced durability, high electrical conductivity

HS Code : 28419000

Maxpas 142 AL

Usage : For manufacturing components requiring lightweight and high strength

Smell : Other, Odourless

Grade : Industrial Grade

Storage : Other, Store in a dry, cool place, protected from moisture and corrosive atmosphere

Properties : High strength, lightweight, corrosion resistant, good electrical conductivity

HS Code : 76012010

Anodal 50EL

Usage : Used as an anode additive for electrolytic coloring and surface finishing

Smell : Other, Characteristic

Grade : Industrial

Storage : Other, Store in tightly closed containers in a dry, cool and wellventilated place

Properties : Specially designed anode brightener for aluminum and aluminum alloys

HS Code : 3824

Industrial Aluminium Brightening Chemical

Usage : Dilute and apply as per manufacturer instructions for cleaning or brightening aluminium surfaces

Smell : Mild chemical odor, Other

Grade : Industrial grade

Storage : Other, Store in a cool dry place away from direct sunlight

Properties : Enhances shine removes oxidation and brightens aluminium surfaces

HS Code : 34029090

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS