Maxpas 142 AL

Maxpas 142 AL Specification

- Molecular Formula

- Al

- Product Type

- Alloy

- Properties

- High strength, lightweight, corrosion resistant, good electrical conductivity

- Storage

- Store in a dry, cool place, protected from moisture and corrosive atmosphere

- Application

- Used in die casting, automotive, electrical, and aerospace industries

- Appearance

- Silver White

- Usage

- For manufacturing components requiring lightweight and high strength

- Density

- 2.7 Gram per cubic centimeter(g/cm3)

- Melting Point

- Approx 660C

- Purity

- Up to 99%

- Shape

- Slab/Ingot

- EINECS No

- 231-072-3

- CAS No

- 7429-90-5

- Physical Form

- Solid

- Structural Formula

- Al

- Grade

- Industrial Grade

- Molecular Weight

- 26.98 g/mol

- Ingredients

- Aluminium, Manganese, Magnesium

- Poisonous

- NO

- Solubility

- Insoluble in water

- Ph Level

- Neutral

- Shelf Life

- Stable under recommended storage conditions

- Smell

- Odourless

- HS Code

- 76012010

- Tensile Strength

- Approx 110 MPa

- Corrosion Resistance

- Excellent against most acids and alkalis

- Thermal Conductivity

- 205 W/m·K

- Minimum Order Quantity

- 500 kg

- Machinability

- Good

- Packing Details

- Packed in wooden pallets or as per customer requirement

- Standard Specification

- Complies with IS/BIS/ASTM/EN standards

About Maxpas 142 AL

Maxpas 142 Al

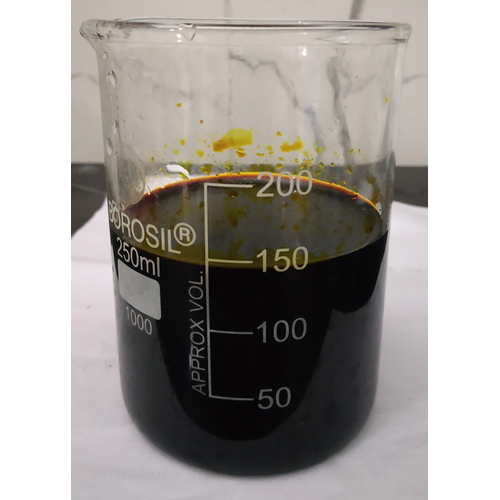

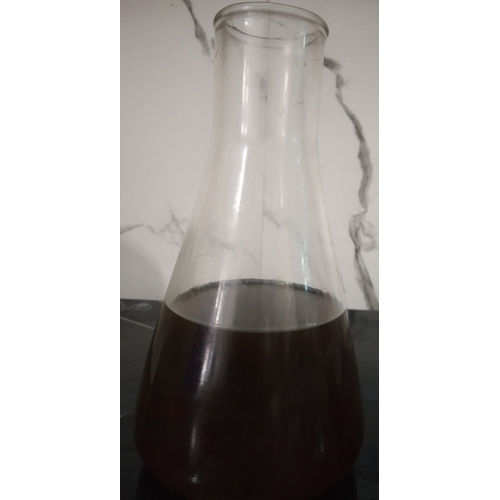

Powder Chrome Conversion Coating Chemicals

| Grade Standard | Chemical Grade |

| Physical State | Powder |

| Packaging Size | 5 kg & 20 kg |

| Packaging Type | HDPE Container |

| Usage/Application | Industrial |

| Color | Brown colour |

| Brand | MAXPAS 142 AL |

| Dilution Ratio | 10 gm/ltr |

| Dipping Period | 30-60 sec |

Outstanding Durability and Resistance

Maxpas 142 AL boasts exceptional corrosion resistance against most acids and alkalis, making it suitable for environments that demand longevity and safety. Its innate durability ensures reliable performance and minimal maintenance across various industrial applications, particularly where exposure to harsh substances is frequent.

Versatile Industrial Application

This alloy is specifically engineered for manufacturing components that require a combination of lightweight properties and substantial strength. Its good electrical conductivity and machinability make it an excellent choice for die casting, automotive parts, electrical equipment, and aerospace components.

FAQ's of Maxpas 142 AL:

Q: How is Maxpas 142 AL typically used in industry?

A: Maxpas 142 AL is predominantly used in manufacturing components for die casting, automotive, electrical, and aerospace applications, where both lightweight construction and high strength are essential.Q: What is the process for ordering and receiving Maxpas 142 AL?

A: Customers can place orders with a minimum quantity of 500 kg. The alloy is packed securely in wooden pallets or customized packing per client requirements and shipped according to the agreed schedule.Q: Where should Maxpas 142 AL be stored to ensure optimal shelf life?

A: Maxpas 142 AL should be stored in a dry, cool space, protected from moisture and corrosive atmospheres. Following these conditions ensures stability and preserves its properties over time.Q: What benefits does Maxpas 142 AL offer compared to other industrial alloys?

A: Maxpas 142 AL provides a unique combination of high purity (up to 99%), strength, corrosion resistance, and lightweight characteristics, making it highly efficient for applications requiring durable, high-performance materials.Q: Is Maxpas 142 AL safe to handle and use in manufacturing environments?

A: Yes, Maxpas 142 AL is non-poisonous and odourless, making it safe for handling and use in manufacturing environments when recommended storage and handling procedures are followed.Q: What are the machining advantages of Maxpas 142 AL?

A: With good machinability, Maxpas 142 AL allows for efficient cutting, shaping, and forming processes, streamlining manufacturing operations, and reducing operational costs and time.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Aluminium Anodising Category

Aluzincate 50B

Smell : Other, Odorless

HS Code : 28419000

Poisonous : NO

Ingredients : Zinc, Aluminum, Additives

Solubility : Insoluble in water

Ph Level : 7.0 8.5

Maxpas 143 AL

Smell : Other, Mild

HS Code : 38244090

Poisonous : NO

Ingredients : Polycarboxylate Ether Base

Solubility : Freely Soluble in Water

Ph Level : 78 (1% Solution)

Anoseal Hs 90

Smell : Other, Odorless

HS Code : 3824

Poisonous : Other, Nonpoisonous

Ingredients : Blend of inorganic fluorides and silicates

Solubility : Partially soluble in water

Ph Level : 9.510.5 (1% solution)

Anoseal 50 LT

Smell : Other, Odorless

HS Code : 2826

Poisonous : NO

Ingredients : Inorganic salts blend, additives for anodized sealing, proprietary chemicals.

Solubility : Miscible in water

Ph Level : 5.06.0

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS