Nickel Antipit

Nickel Antipit Specification

- Storage

- Store in a cool, dry place; keep container tightly closed

- Purity

- 99%

- Molecular Weight

- Not Applicable (Mixture)

- Shelf Life

- 2 Years

- Solubility

- Easily soluble in water

- Smell

- Mild

- Application

- Nickel Electroplating Industry

- Properties

- Excellent anti-pitting properties, improves nickel deposit quality, enhances plating brightness, provides uniform coating

- Usage

- Used to prevent pitting during nickel electroplating baths

- Grade

- Technical Grade

- HS Code

- 3824

- Product Type

- Antipit Chemical (For Electroplating)

- Shape

- Crystalline

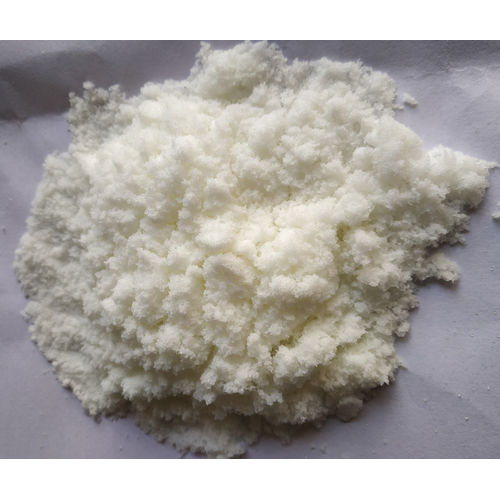

- Appearance

- White Crystalline Powder

- Physical Form

- Powder

- Poisonous

- NO

- Structural Formula

- Not Applicable (Mixture)

- Ingredients

- Organic Additives, Surfactants, Wetting Agents

- Ph Level

- 7 (Neutral)

- Molecular Formula

- Not Applicable (Mixture)

- Minimum Order Quantity

- 25 kg

- Compatibility

- Compatible with various nickel plating solutions

- Safety Precaution

- Use protective gloves and goggles while handling

- Packing Type

- HDPE bags or drums

About Nickel Antipit

Nickel Antipit Applications and Material Features

Nickel Antipit is widely used by leading manufacturers, exporters, and service providers in the nickel electroplating industry. Its main usage lies in preventing pitting during plating baths, ensuring the highest deposit quality. Notable material features include its excellent anti-pitting properties, ability to enhance coating brightness, and capability of delivering a uniform finish across diverse nickel solutions. It is suitable for various industrial applications and requires storage in a cool, dry environment for optimum shelf life.

Nickel Antipit Sample Policy and Shipment Details

Nickel Antipit samples are available for quality validation. Once requested, the sample is duly handed over to reliable logistics partners and shipped from our designated FOB port in India, assuring swift and secure goods transport. Customers can expect the shipment to be dispatched promptly, supported by clear communication at every step. Our sample policy reflects the company's commitment to service excellence, catering to both bulk and custom industry requirements with utmost efficiency.

FAQ's of Nickel Antipit:

Q: How should Nickel Antipit be handled safely during use?

A: Always wear protective gloves and goggles while handling Nickel Antipit to prevent skin or eye contact, and operate in a well-ventilated area for maximum safety.Q: What makes Nickel Antipit beneficial in nickel electroplating?

A: Nickel Antipit provides excellent anti-pitting properties, significantly enhances coating brightness, and guarantees a uniform nickel deposit, thus improving finished product quality.Q: When should Nickel Antipit be introduced into the plating bath?

A: Nickel Antipit should be added at the start of the electroplating process or as recommended by the solution supplier for continuous anti-pitting protection throughout plating.Q: Where can Nickel Antipit be applied?

A: It is primarily utilized in the nickel electroplating industry but is compatible with various nickel plating solutions for diverse industrial and technical applications.Q: What are the packaging options and minimum order requirements for Nickel Antipit?

A: Nickel Antipit is available in HDPE bags or drums to ensure safe transport and storage, with a minimum order quantity of 25 kg per shipment.Q: How should Nickel Antipit be stored for maximum shelf life?

A: Store Nickel Antipit in a cool, dry place; keep the container tightly closed to maintain its 2-year shelf life and preserve performance integrity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Chemical Products Category

Maxphos Tonner 50

Application : Other , Feed additive for poultry, cattle, aquaculture, livestock

Grade : Feed Grade

Usage : As a phosphorus source in animal feed

HS Code : 28352990

Properties : High efficiency phosphorus source, free flowing powder, noncaking

Purity : 50%

Maxphos 1310 chemical

Application : Other , Used as flame retardant in polyurethane, adhesives, coatings, fibers, plastics, and electronics

Grade : Industrial Grade

Usage : Additive for industrial flame retardancy

HS Code : 29199090

Properties : Maxphos 1310 is a liquid phosphorus based halogen free flame retardant; high phosphorus content; good compatibility with polymer matrices; low volatility

Purity : 98% Min

MAXPHOS 172 Z chemical

Application : Other , Surface treatment of steel and iron components

Grade : Industrial

Usage : Used in degreasing and phosphating processes for industrial metal finishing

HS Code : 3824

Properties : Efficient cleaning and phosphating agent for steel surfaces; provides excellent corrosion resistance

Purity : High

Maxflux L /160L Chemical

Application : Other , Textile industry, chemical process aid

Grade : Industrial Grade

Usage : Auxiliary for dyeing, processing chemical

HS Code : 38249022

Properties : Highly efficient, stable composition, suitable for industrial applications

Purity : High Purity

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS