Maxbrite Ni 1733

Maxbrite Ni 1733 Specification

- Melting Point

- 1455C

- Refractive Rate

- Not Determined

- Grade

- Industrial

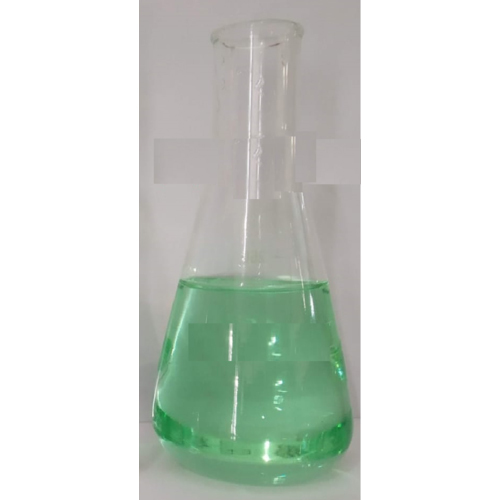

- Appearance

- White to off-white crystalline powder

- Purity

- 99%

- HS Code

- 38159000

- Physical Form

- Powder

- Storage

- Store in tightly sealed container in a cool, dry, and well-ventilated place

- Application

- Nickel electroplating industry

- EINECS No

- 231-111-4

- Molecular Formula

- Ni

- Structural Formula

- Ni

- Ph Level

- Neutral

- Poisonous

- NO

- Shape

- Granular / Powder

- Product Type

- Electroplating Additive

- Smell

- Characteristic

- Shelf Life

- 2 Years

- Ingredients

- Organic brighteners, carriers, and leveling agents in aqueous solution

- Solubility

- Soluble in water

- Properties

- Bright nickel electroplating additive, improves deposit brightness and ductility

- Usage

- Used as an additive in nickel plating baths for obtaining bright deposits

- CAS No

- 7440-02-0

- Density

- 8.9 Gram per cubic centimeter(g/cm3)

- Molecular Weight

- 58.69 g/mol

About Maxbrite Ni 1733

Application Areas and Commercial Uses

Maxbrite Ni 1733 is ideally suited for the nickel electroplating industry, celebrated for its ability to improve deposit brightness and ductility when used as an additive in nickel plating baths. This versatile product is favored by manufacturers, exporters, suppliers, and service providers across diverse industrial sectors where eminent, durable, and aesthetically bright nickel coatings are required. Its rare combination of organic brighteners and leveling agents provides a lasting competitive advantage in commercial electroplating.

Supply Ability and Export Markets

With stock ready for immediate dispatch, Maxbrite Ni 1733 is available in convenient 1 kg, 5 kg, or 25 kg packaging. The asking price is competitively set for bulk orders and global distribution. Maxbrite Ni 1733 is exported predominantly to international markets from India's eminent FOB ports, with efficient transport services ensuring secure, prompt delivery. Our robust supply ability meets both large and customized industrial requirements, offering uninterrupted product availability for clients around the world.

FAQ's of Maxbrite Ni 1733:

Q: How should Maxbrite Ni 1733 be stored for optimal stability?

A: Maxbrite Ni 1733 should be stored in a tightly sealed container in a cool, dry, and well-ventilated place to maintain its stability and effectiveness throughout its two-year shelf life.Q: What makes Maxbrite Ni 1733 a meritorious choice for nickel electroplating?

A: Maxbrite Ni 1733 stands out due to its perfection in producing bright, ductile nickel deposits, high purity levels, and full compliance with industrial safety and quality standards including ISO 9001:2015 certification.Q: When can I expect delivery after placing an order for Maxbrite Ni 1733?

A: With an assured stock ready, dispatch is typically prompt upon confirming the order. Delivery timelines depend on location and shipping method, but efficient transport services are employed to minimize delays.Q: Where is Maxbrite Ni 1733 primarily exported from and to which markets?

A: Maxbrite Ni 1733 is exported from India's major FOB ports and is supplied to international markets, including large industrial hubs requiring reliable nickel electroplating additives.Q: What is the recommended usage process for Maxbrite Ni 1733 in nickel plating baths?

A: Maxbrite Ni 1733 is used as an additive in standard nickel plating electrolytes, where precise dosing ensures optimal brightness and ductility for superior electroplating results.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Chemical Products Category

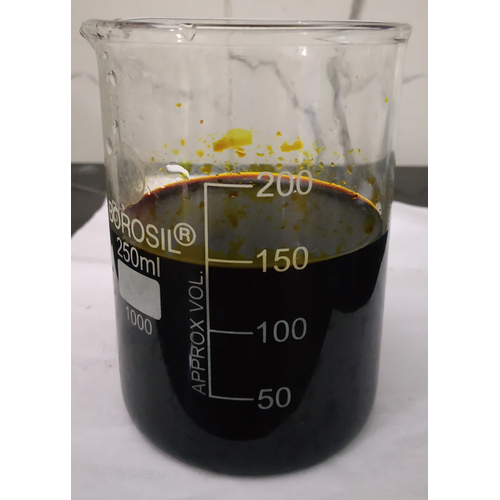

Maxchrome Hc

Appearance : Green fine powder

Grade : Industrial Grade

Storage : Other, Store in a cool, dry place, tightly closed container

Physical Form : Powder

HS Code : 32064990

Purity : 99%

Maxphos Seal 50

Appearance : Clear to pale yellow liquid

Grade : Industrial

Storage : Other, Store in cool, dry, wellventilated area in original container

Physical Form : Liquid

HS Code : 38249090

Purity : 99%

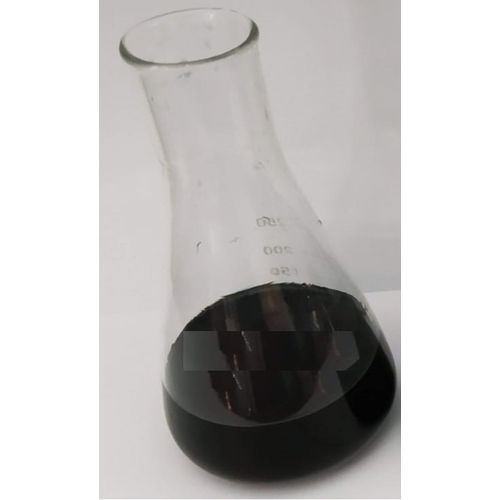

Maxchrome Srhs / Dc

Appearance : Greenish powder

Grade : Industrial Grade

Storage : Other, Store in cool, dry, and ventilated place, tightly closed container

Physical Form : Powder

HS Code : 28415000

Purity : 99%

Maxpas Tc 185

Appearance : White freeflowing powder

Grade : Industrial Grade

Storage : Other, Store in cool, dry place in tightly closed container

Physical Form : Powder

HS Code : 39069090

Purity : >99%

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS