Anodising Additive

Anodising Additive Specification

- Usage

- Added to anodising tanks to enhance efficiency

- Poisonous

- No (when used as directed)

- Density

- 1.15 Gram per cubic centimeter(g/cm3)

- Ph Level

- 2.0 - 4.0

- Purity

- High Purity (>99%)

- Storage

- Store in cool, dry place, away from sunlight

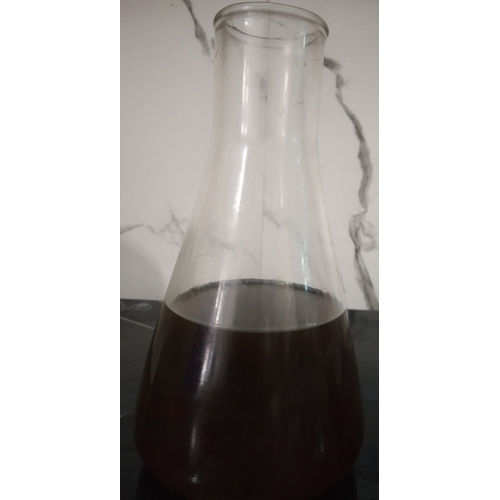

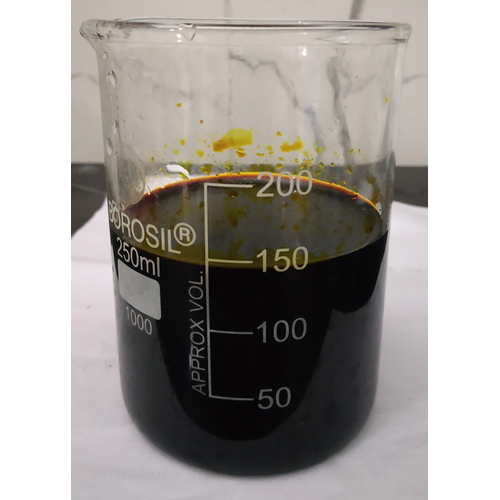

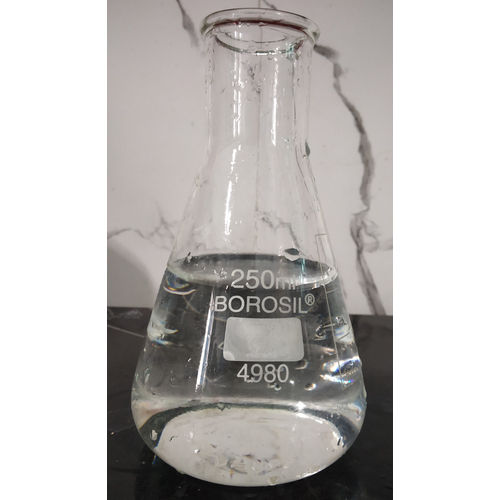

- Physical Form

- Liquid

- Appearance

- Clear to slightly yellow liquid

- Grade

- Industrial Grade

- Product Type

- Anodising Additive

- Ingredients

- Proprietary blend of chemical additives

- Application

- Used in aluminum anodising baths

- Smell

- Mild/Chemical

- HS Code

- 38109090

- Shelf Life

- 12 Months

- Shape

- Liquid

- Solubility

- Miscible in water

- Properties

- Enhances anodising process; ensures uniform finish and improves corrosion resistance

- Compatibility

- Compatible with standard anodising electrolytes

- pH Range (Diluted 1:10)

- 2.5 - 3.5

- Pack Size

- 35 Kg, 50 Kg & 200 Kg

- Flash Point

- Non-flammable

- Packaging Type

- HDPE Drums / Carboys

- Boiling Point

- Above 100°C

- Stability

- Stable under normal conditions

- Toxicity

- Low toxicity as per standard industrial usage guidelines

- Environmental Impact

- Biodegradable, environmentally safe when used as directed

About Anodising Additive

Advanced Usage Versatility for Anodising Baths

Anodising Additive is designed for professional application in aluminum anodising baths and is ideal for enhancing operational efficiency in industrial environments. Type of usage includes direct addition to anodising tanks to boost process effectiveness. Although primarily formulated for aluminum, its tailored blend makes it suitable for other compatible non-ferrous metal applications, supporting a range of industrial anodising scenarios. This product consistently delivers optimum results and suits both large and small-scale anodising operations.

FOB Port, Certification, and Sampling Options

We offer convenient FOB port drop-off for all shipped goods, ensuring your orders are efficiently managed from dispatch to delivery. Certified to meet premier industrial standards, this anodising additive undergoes rigorous quality checks. For your evaluation and peace of mind, samples are available upon request-empowering you to experience product excellence before placing bulk orders. Our commitment to reliable service and certified quality sets us apart as your trusted exporter and supplier.

FAQ's of Anodising Additive:

Q: How should the Anodising Additive be used in anodising tanks?

A: The additive should be mixed into anodising tanks at specified concentrations to enhance process efficiency, improve corrosion resistance, and ensure a uniform aluminium finish.Q: What makes this additive environmentally safe during usage?

A: Its proprietary blend is biodegradable and exhibits low toxicity. When used as directed, it poses minimal environmental impact, making it a responsible choice for industrial applications.Q: When is it best to add the additive during the anodising process?

A: It is recommended to introduce the additive at the beginning of the anodising cycle to allow even distribution and optimal process enhancement throughout the bath.Q: Where can the product be stored for maximum stability?

A: Store the additive in a cool, dry place, away from sunlight, and within HDPE drums or carboys to maintain its stability and effectiveness throughout its 12-month shelf life.Q: What are the key benefits of using this Anodising Additive?

A: Major benefits include improved corrosion resistance, a more uniform anodised layer, compatibility with standard electrolytes, ease of mixing, and enhanced operational efficiency.Q: How does the packaging support industrial usage?

A: The product is securely packaged in durable HDPE drums or carboys, available in 35 kg, 50 kg, and 200 kg options to suit both small-scale and bulk requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Aluminium Anodising Category

Aluzincate 50B

Properties : Good corrosion resistance, enhanced durability, high electrical conductivity

Solubility : Insoluble in water

Shelf Life : 2 Years

Application : Other , Galvanizing, coating for steel, electrical industries, construction

Ingredients : Zinc, Aluminum, Additives

Grade : Technical Grade

Maxpas 142 AL

Properties : High strength, lightweight, corrosion resistant, good electrical conductivity

Solubility : Insoluble in water

Shelf Life : Stable under recommended storage conditions

Application : Other , Used in die casting, automotive, electrical, and aerospace industries

Ingredients : Aluminium, Manganese, Magnesium

Grade : Industrial Grade

Anodal Stabilizer

Properties : Acts as an effective anode stabilizer; helps to maintain bath stability; improves current efficiency; prevents violent oxygen evolution at the anode

Solubility : Miscible in water

Shelf Life : 12 months

Application : Other , Used in anodizing processes for aluminum and its alloys

Ingredients : Specialty organic and inorganic compounds blend

Grade : Technical Grade

Maxclean 300L

Properties : High efficiency, suitable for large scale cleaning, gentle on surface

Solubility : Completely soluble in water

Shelf Life : 12 months

Application : Other , Industrial cleaning, large surface washing, institutional hygiene

Ingredients : Proprietary blend of surfactants, water, cleaning agents

Grade : Industrial Grade

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS